Cable Insulation

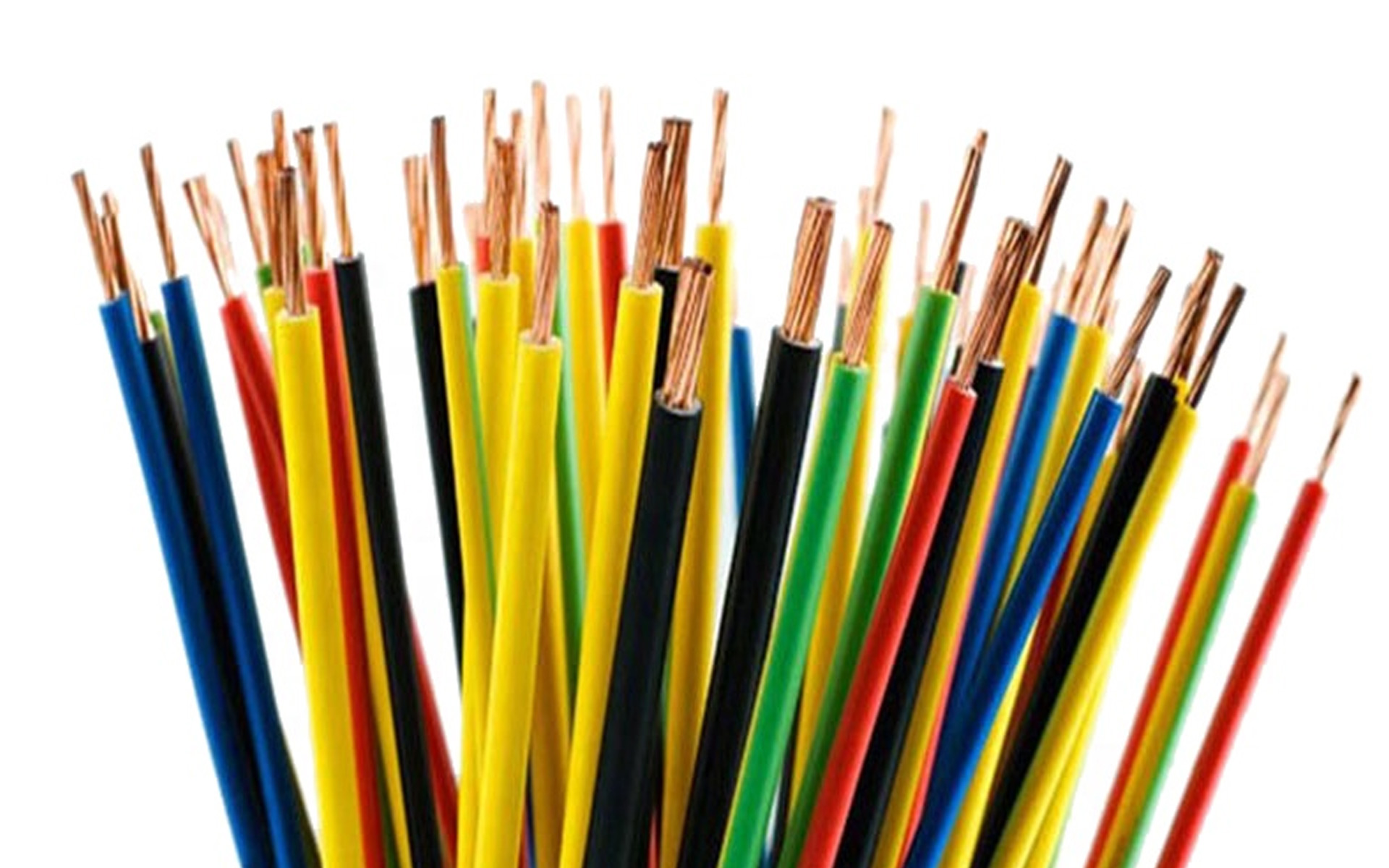

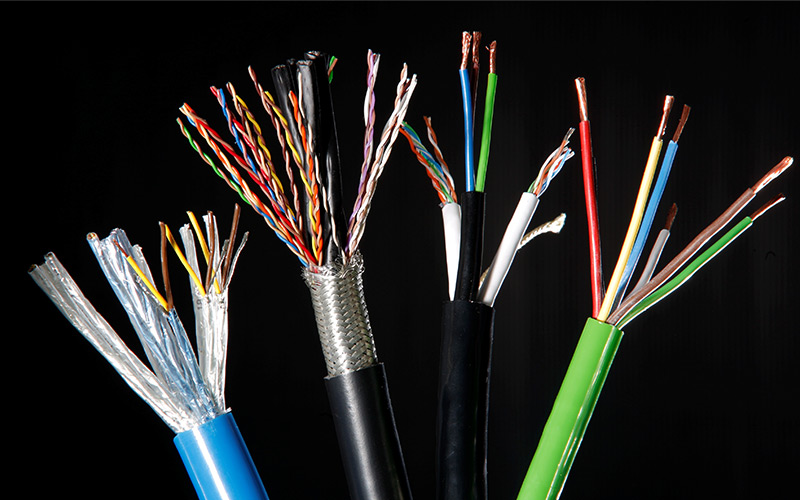

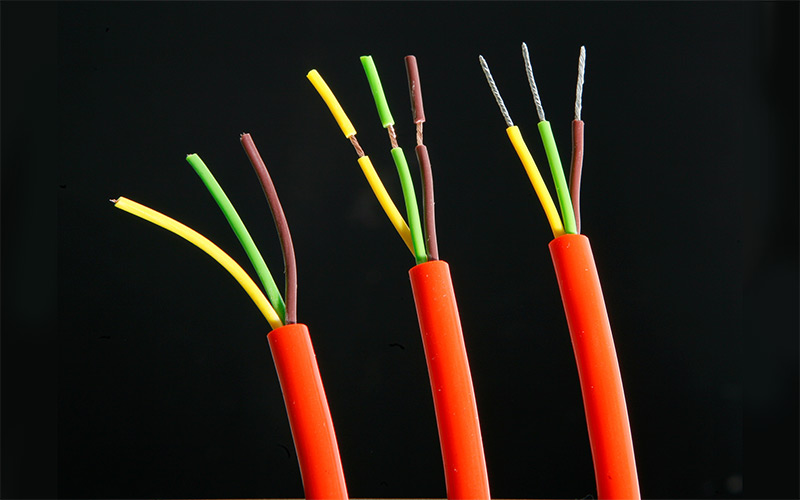

Kalestead offers an extensive range of thermoplastic materials for electrical insulation. These materials may be used over the conductors (to make cores) and over the whole cable (to make a protective jacket, or sheath).

Some of the cables we make have more than one sheath. This is common in submersible cables or where extra protection/insulation is required within the cable.

Our thermoplastic compounds cover a huge range of physical and thermal properties.

Insulating

The customer has a bewildering number of materials to choose from. Here are just a few of the aspects to consider:

- Hardness, flexibility and durability

- Temperature range

- Chemical, atmospheric and microbial resistance

- Behaviour when burning – flammability, emissions, flame propagation

- Electrical characteristics – resistivity, dielectric properties for desired capacitance and impedance

- Finish and appearance

- Colour

- Cost

Just as a guide, please see our ‘Range of Materials’ – Extrusion table on this website.

This does not cover all the materials we have at our disposal. Talk to our Sales team and together we will find the best solution for your application.

Additives

In addition to the wide range of colour masterbatches we hold in stock, we can offer a colour shade to match your original equipment or a bespoke colour to give your product added impact.

We also offer additives to dissipate static charges or to enhance resistance to fire, heat, UV or fungal/microbial attack.

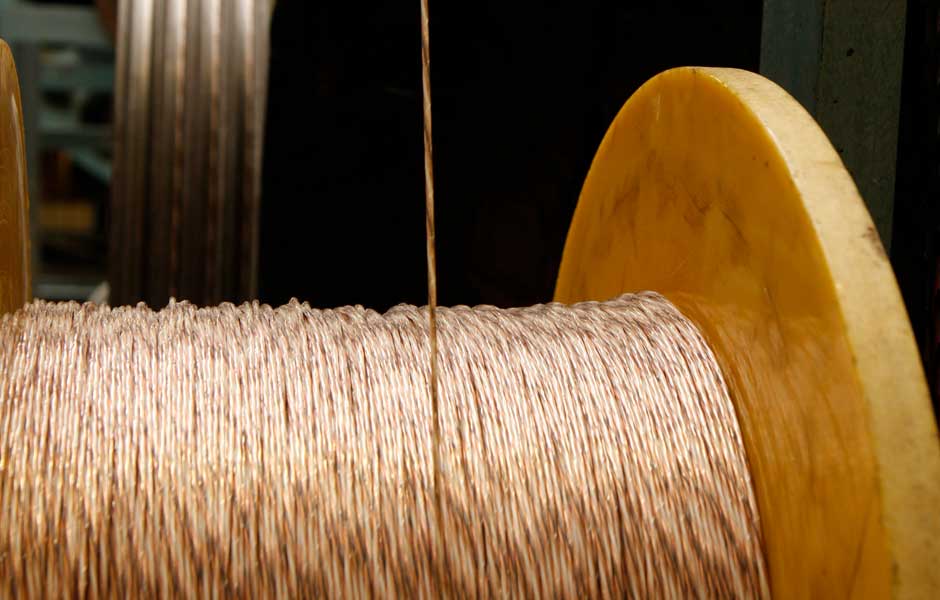

Conducting

Kalestead also offer conductive and semi-conductive materials for internal or external coating of cables. These can, for instance, be useful for noise reduction in audio cables or to reduce the effects of static electricity build up between polarized materials.

Contact us

If you have a project and require assistance, do not hesitate to contact us. A member of our team will be in touch.